Tailored Control Systems

System Overview

- Description

- System Details

We are constantly engaged by our clients to develop monitoring and control systems fitting their ambitious projects to realize challenging and complex tasks in the maritime industry. Therefore, Hoppe Marine has been always expanding its capabilities to meet their customer requirements. Our ability to respond to these challenges by providing cost-efficient and tailored systems makes us a reliable partner in the market. We have reintroduced FLUME® type roll damping tanks on container ships. The damped motion response of the vessel results in decreased lashing forces and is used to boost container intake. The development of the Load Moment Control algorithm has enabled our customer to undertake heavy lifts automatically.

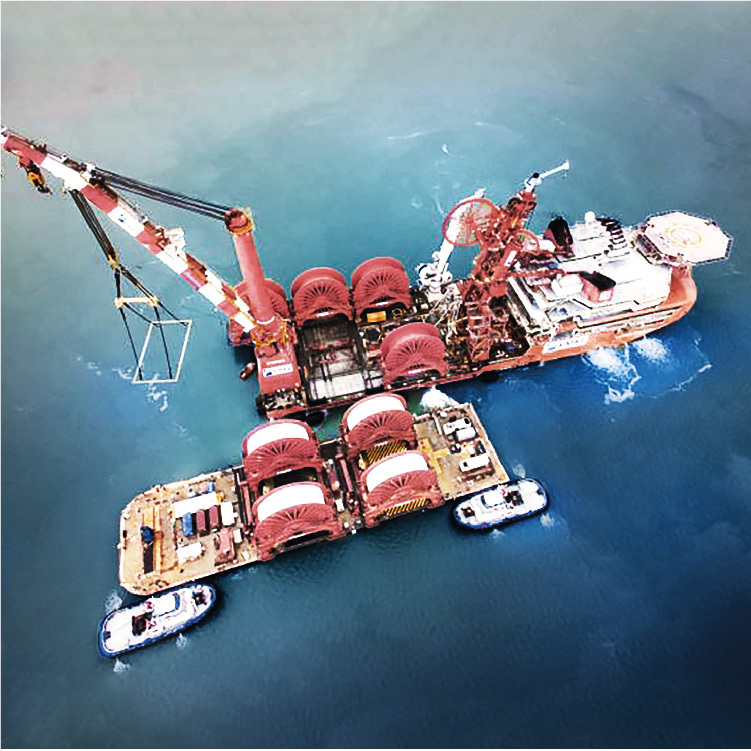

All our offshore clients, such as Heerema, DEME, EMAS and others, are benefiting from this technology leap, which provides high heel compensation rates in an instant at a high accuracy level. Projects with a single crane, located on starboard, off center-line, with crane lifting capacities up to 4,000 t have been realized to undertake heavy lifts fast and safely, even at sea. Recently, the algorithm has been further enhanced to enable automatic dock operations of floating, construction and combi docks or heavy transport vessels. The load moment is either measured or predefined in the loading computer. Simulations of the entire sub-/emergence procedure are undertaken under consideration of the operational limitations, such as trim, heel, draft, deflection and intact stability. A Dock Operation Computer is automatically executing the simulation considering the hydrodynamic behavior of the ballast system and the respective ballast pumps.

Reducing Lashing Forces

Hoppe Marine has reintroduced FLUME® type passive roll damping tanks to container ships. At present, more than 50 container vessels ranging from small (2 k TEU) to ultra large (20 k TEU) have been equipped with the system. Customers benefiting from the technology are well established liner giants such as MAERSK and innovative niche market operators. The technology has been installed to utilize the positive effect of the reduced roll angles and associated accelerations on the magnitude of the lashing forces. The application allows to increase cargo intake and to store heavier containers more flexibly. Even for retrofits, the nominal number of container tiers and the maximum storable weight of each individual container has been increased.

Increasing Ice Breaking Capabilities

For icebreakers and vessels with ice-breaking capabilities Hoppe provides a specialized ice heeling system. The blower-driven Heel Control system is utilized to actively generate a continuous heeling motion from port to starboard and back. Only the fast reacting and high capacity blower unit is able to generate the required large heeling moment in the required short time span.

Simulating Loading Operations

Hoppe Marine provides onboard software solutions to simulate offshore operations, heavy lifts or automatic loading transfer operations, like the docking of a vessel in a floating dock or on a heavy transport vessel. The simulators are based on the loading computer infrastructure Colos. The aim is to support the shipboard personnel with a reliable and realistic tool to undertake the planning of the respective operation. Besides all standard modules, such as intact and damage stability and longitudinal strength, special modules for cargo handling are provided. In addition, hydrodynamic characteristics of pumps, hydraulics of the ballast piping, valves and tanks are implemented in order to ensure realistic simulation results. In combination with Hoppe Marine’s Valve Remote Control, Tank Content Measurement, pump control and vast number of the monitoring system, we even offer an automatic execution of the simulated operation. In these cases the simulator supervises the execution and optimizes the target values so that operational limits such as trim, heel, deflection and stability requirements are fulfilled. The loading computer software including the simulator is also available as an office version.

Controlling Load Moments

Hoppe Marine supplies complex and sophisticated Heel Control systems which keep ships upright during construction, heavy lift and offshore installation operations. For clients, such as Heerema, DEME and Subsea 7, the Load Moment Control (LMC) algorithm has been developed.

The novel working principle is: “ballast follows the crane” by generating the exact amount of heel moment required to counteract the crane’s righting moment. The flow of each individual heeling pump can be continuously adjusted between “zero-flow” and the maximum flow capacity. LMC ensures a smooth, uninterrupted and safer crane operation at significantly reduced operation time. Hoppe’s advanced Heel Control systems are capable to keep the maximum heel angle below ± 0.5 degrees.

Enabling Automatic Dock Operations

Floating docks and semi-submersible heavy transport, decommissioning and multi-purpose dock vessels undertake sub-/emergence operations to lift marine structures and ships. Hoppe’s Dock Control systems offer automatic ballast operations. Ballast operations are automatically undertaken under the control of the loading computer. Draft, trim, heel, deflections and stability requirements are controlled to not exceed the operational limits.

Computer Aided Inclinning Test

The Stability Test system provides the exact actual GM of the vessel by carrying out a Computer Aided Inclining Test (CAIT). The required heeling moment is achieved by the Hoppe Heel Control system. During the test draught, the heeling tank contents and heel angle are measured by Hoppe’s tank and draught measuring sensors.