News

Current information about COVID-19 / Coronavirus impact

Dear Customers and Partners,

the Coronavirus and the measures to limit the spread of the disease affects many parts of the economic and social activities in most countries of the world. It is still too early to assess all possible effects on the supply chains - in particular because the outbreak and the taken measures differ country specific in time and scope.

Hoppe is closely following developments related to the outbreak of the COVID-19 (Coronavirus SARS-CoV-2) and supports measures of the authorities. Our main goal is to ensure the safety of our employees and suppliers and to minimize the impact of the virus on our customers.

Due to legal rules and disorders along the supply chain, there is a possibility that service deployments or deliveries cannot be fulfilled.

Please take notice of the following information:

Service deployment / Installation

- Entry requirements and legal regulations allows us only to carry out services in countries and areas that are not classified as risk areas and allow entries

- Inquiries for services will be individually evaluate by legal and risk aspects.

- We hope for your understanding, that some services must be relocated or postponed until the risk situation has changed.

Deliveries of goods

- Some suppliers and logistic companies have problems to deliver planned products or materials in time.

- At the moment, we assume that most of planned deliveries can be fulfilled.

- In case a delivery is delayed, we will inform immediately.

Internal measures

- National and international visits are minimized and individual evaluated by risk aspects.

- Our employees are informed and prepared to minimize risks and to act accordingly.

- Emergency plans has been developed and are updated if changes occur, e.g.

- As far as possible employees work remote in the home office, in different shifts or in split teams.

- Some processes are digitalized or modified to optimize remote work.

Thank you for your understanding and best regards

Hoppe Marine GmbH

This document will be updated regularly.

For deeper and background information about the Coronavirus we recommend the following websites:

World Health Organization (WHO): https://www.who.int/health-top...

Robert Koch Institut: https://www.rki.de/DE/Content/...

Hoppe at the Marintec 2019 in Shanghai

The participation at the MARINTEC in Shanghai (3 - 6 December 2019) is a mandatory event for Hoppe Marine. Besides the SMM in Hamburg this fair is one of the best opportunities to talk to important shipbuilders as well as representatives of many well-known shipping companies about current projects and our innovations.

This year Hoppe Marine presented, besides our classic products like Valve Control and Tank Content Measurement Systems, especially our solutions in the field of data quality and ship to shore data transmission as well as the visualization of complex Anti Heeling Systems. But also the fuel consumption saving potentials as well as additional income by the use of our FLUME Roll Stabilization System were well received by our guests.

Due to the very positive response to our trade fair appearance, it is a matter of course for us to be represented again at the MARINTEC in 2021.

Hoppe at the Kormarine 2019

For many years now, Kormarine has been one of the most important fairs where Hoppe Marine exhibits its products and where a good exchange with customers and partners takes place.

Also in 2019 we were able to meet many visitors at our booth and could convince them of the advantages of our Electronic Inclinometer as well as our thoughts about Vessel digitalization process and validated data.

We would like to thank our friends from Hoppe Korea, with whom we have carried out our trade fair appearance, for their support.

Hoppe on Sea Asia 2019

This event was held at the MBS (Marina Bay Sands, Singapore) from 9th Apr till 11th Apr 2019.

HOPPE focus was on Floating Dock Control Systems, Anti-Heeling (AH) and Roll Damping (RD) systems for Heavy Lift vessels. In addition HOPPE’s latest development of Electronic Inclinometer and Hoppe’s inertial measurement system HOSIM for ship movement reporting, the sensor Toolbox HOSET for On board Sensor Diagnostics / Analysis and the hybrid cable HOCAB for Pneumatic valve control systems were also exhibited.

Inclinometer and HOSIM were the attention grabbers of the visitors at the exhibition. There were several visitors interested in AH & RD systems to ensure stability and safety of heavy lift crane operations. HOPPE sensor reliability and cost effectiveness also received much attention of the visitors at the exhibition.

The message that HOPPE Singapore is not only a sales office but also a service center with competent service engineers and spares inventory was also re-enforced at the exhibition. It was a positive event to further create visual awareness of the HOPPE brand and local presence. Visitors were able to revisit the products and service offerings of HOPPE and got the latest updates.

Hoppe on Exposhipping Istanbul

The participation at the Exposhipping Istanbul was again a very successful event for Hoppe Marine. Irena Bittorf and Harry Amtsberg had many good conversations with shipyards, ship owners and designers.We would like to thank our partners from ARTI Denizcilik for the organisation of our trade fair appearance and wish both of us continued good business.

A roll damping system from Hoppe Marine ensures stability on the winner of the "Offshore support vessel of the year Award"

We congratulate Sovcomflot and Arctech on winning the "Offshore support vessel of the year Award" from the Offshore Support Journal for the vessel Yevgeny Primakov. This 104 meter ice-breaking support vessel, the last of a series of four, was built to withstand the harsh conditions of Sakhalin and is therefore equipped with a Hoppe Marine roll damping system.

Hoppe on SMM Hamburg.

We would like to thank our guests for the good talks during the SMM 2018 and look forward to further cooperation and great projects

Hoppe Singapore is operational

It is our great pleasure to announce the opening of Hoppe Singapore office, a wholly owned subsidiary of Hoppe Group, HQ in Hamburg, Germany.

Hoppe Singapore set up adds to the already existing network of Hoppe Marine in China and South Korea further strengthening Hoppe’s commitment in ensuring a reliable and timely response on service and spares support to customers in the region.

Hoppe Singapore is headed by Dr Wilfred Rachan as Managing Director with his team of Service Engineers and Administration staff. In addition to its role as a Sales and Services office, Hoppe Singapore shall also be the spares and logistics hub for Hoppe Marine operations in the region. During the current challenging maritime market, Hoppe Singapore’s goal is to provide quality services and spares efficiently and economically to ship owners and operators in the region.

This investment in Singapore is a reflection of Hoppe Marine’s commitment to the customers that Hoppe is here to stay for the long term. Hoppe Singapore is positioned to provide sales and services support to Ship Design Offices, Shipyards, Ship owners and ship operators. Local presence of qualified and trained service engineers coupled with local availability of quality spare parts and tools are key to ensure competency in service delivery to our customers in the region.

Please do not hesitate to contact us, we would feel much obliged to be of service to you.

Contact:

18 Boon Lay Way, #04-93 Tradehub 21 Singapore 609966

| Office Phone: | +65 6717 4888 |

| Fax: | +65 6931 3988 |

| E-Mail: | service.singapore@hoppe-marine.com |

Hoppe Marine on MARINTEC China 2017

Launched for over 30 years, Marintec China has become renowned as the most authoritative B2B platform for the International Maritime Industry. As in previous editions of this biennial event Hoppe was delighted to welcome many visitors across the complete maritime range during 5-8 December 2017.

Our booth personnel on this important event represented staff from all Hoppe locations worldwide. We had the opportunity to discuss current projects as well as the market development and outlook with our customers and partners. It was generally agreed that the preceding business year seemed to turn out well and that this positive trend will continue in 2018.

The most addressed topics were the HOPPE Marine Tank Content Measuring System which continuously monitors the contents and temperatures of ballast, cargo, fuel oil, and other liquid tanks, our Valve Remote Control System, designed for remote control of pneumatic, hydraulic or electro-hydraulic operated valves and our newly developed Electronic Inclinometer which displays actual roll and pitch data in real time according to IMO res. MSC.363(92).

Summarizing, we can say that the event was a great success and we are looking forward to continuing a prosperous business in China.

Hoppe Marine at the INMEX 2017

Hoppe Marine participated in one of the leading South Asia`s Maritime Exhibitions: Inmex SMM India in Mumbai last week.

We as well as our local Sales ambassador Navicom were delighted to advertise and demonstrate our solutions to interested visitors.

The biggest fields of interest were our unique FLUME® Stabilization System which helps reducing roll motion of ships by up to 90 % and our newly developed Electronic Inclinometer which displays actual roll and pitch data in real time according to IMO res. MSC.363(92).

Many visitors represented the Navy, for which we developed various sophisticated systems and solutions in the past years.

Hoppe Marine on EUROPORT Rotterdam 2017

Hoppe Marine on EUROPORT Rotterdam 2017

During 7th to 10th November 2017 one of the world’s leading exhibitions for maritime technology, Europort was held. Europort has a strong focus on special purpose ships including offshore vessels, dredging vessels, construction vessels, naval vessels, workboats, inland vessels, fishery vessels and super yachts.

Our German colleagues Ms. Dorothee Gaedeke (Sales Manager) and Mr. Joern Rohde (Senior Customer Relation Manager) welcomed many existing and potential customers on the booth of our sales ambassador TBU (BV Technisch Bureau Uittenbogaart).

Besides the HOPPE Sensor Toolbox HOSET 2.0 which is an essential maintenance tool for any ship’s crew for checking, calibrating and exchanging of tank sensors independently, a main topic had been our very accurate and reliable MAIHAK shaft power meter using the Maihak vibrating string sensor. Another principal topic was our unique FLUME® Stabilization System which helps reducing roll motion of ships by up to 60 %.

System and sensor validation – the basis for product development and meaningful data analysis

The validation of data quality and measuring accuracy of related systems and sensors is a mandatory prerequisite for any meaningful data analysis with resulting product development and steady quality improvements. Therefore the standardised Validation Catalogue is executed preceding each system or ship operations analysis that is performed by Hoppe Marine. As a manufacturer and redistributor of high precision measuring equipment and systems for the maritime industry and service provider for standardized and individual data solutions, Hoppe Marine combines unique know-how in the industry.

The data quality section of the Validation Catalogue focuses on data loss, signal mapping, scaling factors and systematic deviations. Implausible value ranges are automatically detected and highlighted. A proactive approach and close cooperation with the service and software department, as well as our customers, guarantees fast detection and correction of causes of error.

The measuring accuracy section of the Validation Catalogue focuses on plausibility and deviation of the measurements of related systems and sensors. Hoppe Marine’s own measuring equipment, like the MAIHAK Performance Meter and flow meters, can hereby be analysed to the very last detail. This enables us to locate the exact source of error in advance, streamlining service operations and saving time and money for our customers. In addition third party equipment, such as speed logs and wind sensors, can be validated to ensure correct functionality.

Knowledge gained from data analysis is also used to develop and improve our hardware and software solutions. For example in 2016 an algorithm was introduced to the MAIHAK Performance Meter software to self-identify zero point drifts and prompt the crew to perform a calibration accordingly. Calibration procedures are logged and can be accessed retrospectively, allowing to prove the proper functioning and accuracy of measuring equipment, for example to comply with standards such as ISO 50001.

The Validation Catalogue by Hoppe Marine is the base for all other standardized data solution products such as the Analysis Catalogue, Fleet and Voyage Comparisons and individually customized analyses. It ensures the highest standards of data quality and measuring accuracy and thereby allows to focus on content-related analysis.

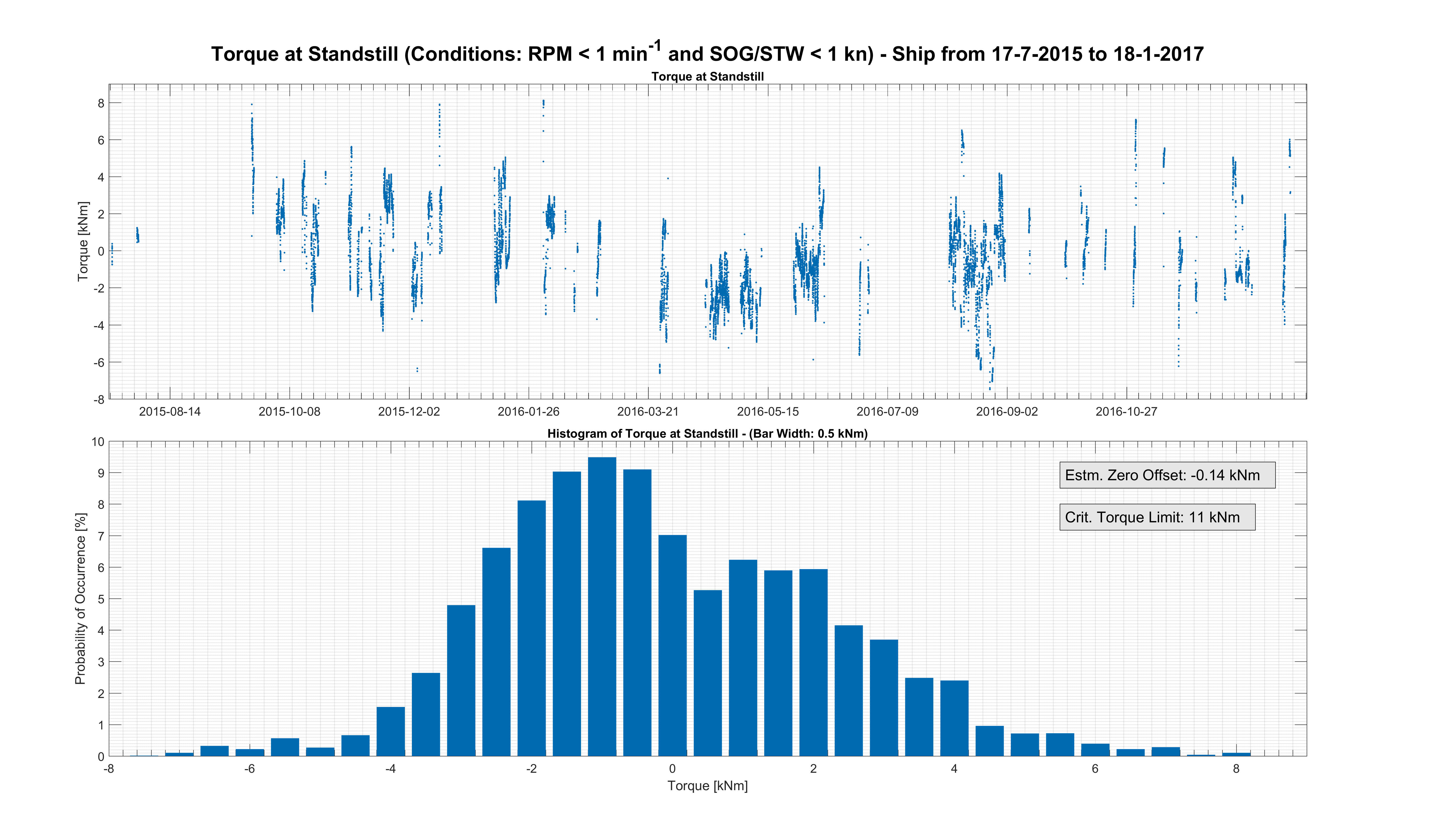

The above figure Torque at Standstill is used to validate the zero point offset of a MAIHAK Performance Meter’s torque measurement at standstill. It is based on the hypothesis that even though tidal and river currents can induce some torque into the shaft during standstill, on average the measured torque should be zero for a representative data set.

The first subplot displays the torque during standstill over time. It can visualize zero point shifts over time or special events such as maintenance or recalibration of the sensors.

The second subplot displays the same data as a histogram to highlight the distribution of the deviation from zero.

In the above case the sensors show optimal behaviour with an average zero offset of only -0.14 kNm and all deviations being well within the ship specific limits of 11 kNm. Additionally no zero point shift over time can be seen. The conclusion is that the data can be trusted and used for further data analysis. The hardware is in good order and no recalibration or maintenance is required.

Hoppe Marine on KORMARINE 2017

We would like to express our sincere thanks and appreciation to all visitors on our booth during South Korea’s Maritime Exhibition KORMARINE 2017. The 20th edition of KORMARINE was held during 24th - 27th October and successfully closed thanks to many interesting and fruitful discussions with existing and potential customers.

Main topics had been HOPPE Marine Valve Remote Control System, designed for remote control of pneumatic, hydraulic or electro-hydraulic operated valves, our very accurate and reliable MAIHAK shaft power meter using the Maihak vibrating string sensor as well as our unique FLUME® Stabilization System which helps reducing roll motion of ships by up to 60 %.

Our local staff from Hoppe Korea, supported by their German colleague Mr. Carsten Rüpcke, advertised and demonstrated our solutions to interested visitors who represented shipyards as well as shipping companies.

Hoppe Marine GmbH takes over Rolls-Royce’s Intering Business

After careful consideration Rolls-Royce Marine Deutschland GmbH has sold its Intering business to Hoppe Marine GmbH, Hamburg. The trade and asset sale is part of Rolls-Royce’s ongoing commitment to concentrate on areas of its core business. The transfer becomes effective on 8 May 2017. From then on Hoppe Marine takes over new building projects as well as related service and spares activities on a successive basis.

The sale includes U-Tank-Systems for roll damping, Blower Anti-Heeling Systems on seagoing ships, as stand-alone or combined solution, and furthermore pump-based Anti-Heeling Systems, also providing an automatized in-service-inclining-test option. With this acquisition, Hoppe Marine now offers the world’s broadest expertise in tailormade, optimized solutions for anti-heeling and passive roll damping systems, under the well established brands Intering, FLUME® and Hoppe.

Marc Rohde, Managing Director and shareholder of Hoppe Marine GmbH, states: “We are delighted to announce the agreement with Rolls Royce. With the acquisition of Intering, Hoppe Marine can further consolidate and expand its leading-edge competence on the field of anti-heeling and passive roll damping solutions (Motion Control), a sector which is of key importance for safe and efficient cargo and passenger shipping, but also for navy and coast guard ships as well as for safe working conditions on offshore vessels. The broad experience portfolio, which Hoppe Marine has accumulated from thousands of successful Hoppe and FLUME® systems, will now be ideally complemented by the Intering line.”

Janne Silden from Rolls-Royce Marine Deutschland adds “We are convinced that our former Intering customers will be in good hands at Hoppe Marine, and we will continue to focus on our core products and capabilities. We wish Hoppe Marine well for the future.”

Hoppe Marine GmbH is a family owned leading supplier of marine systems with main seat in Hamburg / Germany. Hoppe Marine offers innovative and reliable products and system solutions for ships and other maritime applications in the competence areas “Fluid Management”, ”Motion Control” and ”Ship Performance”. During the past years approximately every eight new built seagoing vessel is sailing with Hoppe products on board. Hoppe Marine maintains a world wide service network. Hoppe employs world wide about 150 well qualified staff, in the Hamburg headquarter as well as in its own affiliates in Korea, Chinas and Poland.

Contact:

Stefan Winkler

Team Manager Motion Control

Tel.: +49 (0) 40 561949 0

intering@hoppe-marine.com

Rolls-Royce has a world-leading range of capabilities in the marine market, encompassing vessel design, the integration of complex systems and the supply and support of power and propulsion equipment. We are leaders in mission-critical systems for offshore oil and gas rigs, offshore, merchant and naval vessels.

Today the Rolls-Royce marine product range is one of the broadest in the world. 70 of the world’s maritime forces and over 30,000 commercial vessels use our equipment. Our global support network underpins all activities and continues to expand with 50 centres in 28 countries with more planned.

Contact:

Craig Taylor

Head of Communications

Tel.: +44 (0)1332 632 612

craig.taylor2@rolls-royce.com

Anette Bonnevie Wollebæk

Communications Manager – Nordic Region

Tel.: +47 815 20 070

anette.bonnevie.wollebaek@rolls-royce.com

Seminar ISO 19030 - Measurement of Changes in Hull and Propeller Performance

Open Seminar ISO 19030 - Measurement of Changes in Hull and Propeller Performance

ISO 19030 outlines general principles for the measurement of changes in hull and propeller performance and defines a set of performance indicators for hull and propeller maintenance, repair and retrofit activities.

When: Wednesday September 27th 2017, 14:30 – 17:00

Where: Office VDR, Burchardstraße 24, 20095 Hamburg

Agenda:

1. Welcome, Introduction of speakers

2. ISO 19030 – introduction of the first edition

3. Application Examples – ISO 19030 in use

4. Coffee break

5. Partners‘ Forum /audience discussions

- Reederei Claus-Peter Offen

- Reederei E.R. Schiffahrt

- Hoppe Marine

6. Summary and close

Important/please note:

Participation is free of charge, but registration via e-mail to sales@hoppe-marine.com

is required.

FLUME® roll damping tanks for the Eimskipafélag Íslands hf. and Royal Arctic Line A/S newbuildings

The three recently ordered 2150 TEU Container vessel newbuilding, designed by Deltamarin Ltd are optimized to operate in the harsh ocean environment of the north Atlantic. In this area you never can expect a calm sea and the risk for ships to come in bad weather situations is high. The seakeeping performance of these vessels is therefore under a special concern in the design, why each of these vessels will be equipped with two FLUME® roll damping tanks.

These tanks are designed to fit into the ship structure without any loss of container storage capacity. The tank design will be exactly aligned with the ships loading scenarios and the internal structure of the tank will be optimized using most modern CFD tools. For the final performance evaluation, Hoppe Marine uses a 6 DOF moving platform, capable to simulate any ship motion and measure the tanks performance of that particular scenario.

This project is the 6th most modern container ship class equipped with a FLUME® roll damping tank from Hoppe Marine. While for this project the intention of the tank installation is mainly crew comfort and safety, FLUME® roll damping tanks nowadays are an attractive solution to increase the loading flexibility and the overall container storage capacity of ULCVs (Ultra Large Container Vessels) by up to 10%. For further information about possibilities of roll damping tanks on Container or other Vessels, please contact sales@hoppe-marine.com

Hoppe supplied marine systems for every tenth vessel new built 2013 world wide

Hoppe Marine with headquarters in Hamburg and affiliates in Busan (Hoppe Korea) and Shanghai (Hoppe China) supplied almost every tenth new vessel > 1.000 GT built in 2013 worldwide with it’s quality marine systems. The largest share is with Fluid Management Systems, predominantly Valve Remote Control and Tank Content Measuring, closely followed by Motion Control Systems such as Anti-Heeling- and passive Roll Damping-Systems.

Many of the orders were for Container Vessels (among them also Ultra Large CV) and Offshore Vessels, but Hoppe contracted also for RoRo- and Passenger Vessels, Bulk carriers and Tankers. Additionally to the supply for newbuildings Hoppe Marine has retrofitted several vessels in 2013 with MAIHAK Shaft Power Meters and Performance Monitoring Systems as well as with FLUME® Anti-Rolling Tanks.

MAIHAK Ship Performance Monitoring is setting new standards in on board performance data logging

To monitor consistent ship performance KPIs or to prove the impact of optimization measures like trimming or new bow or propeller shapes appears often like searching for a pin in a hay stack, since aggregated errors from the data recording as well as the lack of possibility to record and analyze the impact of all involved parameters may lead to standard deviations larger than the expected optimization impact. This is why Hoppe Marine is developing and testing a comprehensive data logging and analysis system under real sailing conditions around it’s quality measuring systems MAIHAK Shaft Power Meter, Hoppe Tank Content Systems and Mass Flow Meters, Hoppe HOSIM Dynamic Floating and Inertial Ship Motion Measuring System and TRIMCON Dynamic Trim Measurement.

Core of the System is an onboard data logging system with intelligent algorithms to pre-process continuous input from Hoppe’s and external measuring devices, which can also deliver data to overarching shore transmission and fleet management systems (e.g. Interschalt BLUE TRACKER). Since September 2011 first elements of the MAIHAK Ship Performance Monitoring Systems in different versions and depth are successfully in on board operation (including top operators like Bernhard Schulte and HAPAG Lloyd). In spring 2014 another large operator has decided after a trial period to install a first MAIHAK Ship Performance Monitoring System level on dozens of his fleet’s vessels, in combination with BLUE TRACKER.

Hoppe’s MAIHAK Ship Performance Monitoring System provides the key function of logging, managing and understanding data on board, without which every fleet management program would still search the pin in the hay stack.

FLUME® Roll Damping Systems kept Container Vessels upright in stormy Bay of Biscay

Hoppe Marine has gained valuable feedback from some Container Vessels equipped with the FLUME® Stabilization System during their passage through the Bay of Biscay in heavy winter storms early 2014.

On a 8700 TEU- Vessel the data Logging equipment installed with the FLUME® tank recorded 5-6 degree significant roll angles with maximum peaks up to 10 degrees during the worst hours, while a vessel of similar size and load condition without FLUME® tank, which followed some miles back on same course reported mean values of estimated 15-20 degrees.

This was impressive evidence how FLUME® passive roll damping Systems can contribute to a safer passage for crew and cargo.

FLUME® Product Video

The FLUME® Product Video demonstrates to what extend a FLUME® Stabilization System can contribute to reduce roll motions of sea going vessels.

FLUME® Stabilization Systems are installed on many different types of vessels e.g. Offshore Vessels, RO-RO Ferries, Naval Vessels and Containerships. A FLUME® Stabilization System is a passive free surface open channel type roll damping tank. It is partially filled with water and extends across the full beam of a ship. The tank is designed to create a stabilizing moment which counteracts the wave moment causing the ship's roll motions. It has the unique ability to adapt to changes in load and operation condition. By a change in the liquid level, the natural response period of the tank is adjusted to correspond to the roll period of the ship.

The FLUME® Product Video compares the impact of sea motions on a ship without a stabilization system and a ship with a FLUME® installation.

For further information you can check our publications in the download area or contact us at info@hoppe-marine.com.

2020

- Current information about COVID-19 / Coronavirus impact

2019

- Hoppe at the Marintec 2019 in Shanghai

- Hoppe at the Kormarine 2019

- Hoppe on Sea Asia 2019

- Hoppe on Exposhipping Istanbul

- A roll damping system from Hoppe Marine ensures stability on the winner of the "Offshore support vessel of the year Award"

2018

- Hoppe on SMM Hamburg.

- Hoppe Singapore is operational

2017

- Hoppe Marine on MARINTEC China 2017

- Hoppe Marine at the INMEX 2017

- Hoppe Marine on EUROPORT Rotterdam 2017

- System and sensor validation – the basis for product development and meaningful data analysis

- Hoppe Marine on KORMARINE 2017

- Hoppe Marine GmbH takes over Rolls-Royce’s Intering Business

- Seminar ISO 19030 - Measurement of Changes in Hull and Propeller Performance

- FLUME® roll damping tanks for the Eimskipafélag Íslands hf. and Royal Arctic Line A/S newbuildings

2014

- Hoppe supplied marine systems for every tenth vessel new built 2013 world wide

- MAIHAK Ship Performance Monitoring is setting new standards in on board performance data logging

- FLUME® Roll Damping Systems kept Container Vessels upright in stormy Bay of Biscay

- FLUME® Product Video