Heel Control

System Overview

- General

- Key Features

- Components

Hoppe is one of the leading suppliers of Heel Control systems in the maritime industry. The portfolio ranges from costeffective standard solutions to tailored and highly sophisticated systems for complex and specialized applications. Heel Control systems are designed to keep any kind of vessel or offshore structure upright with respect to the permissible heel angle limit. The righting moment arising, causing the heel angle, is compensated by shifting ballast water between a set of heeling tank pairs located vis-a-vis on starboard and portside within the ship. The water transfer is achieved by utilizing centrifugal, reversible propeller, or screw-pumps and even air-blower units.

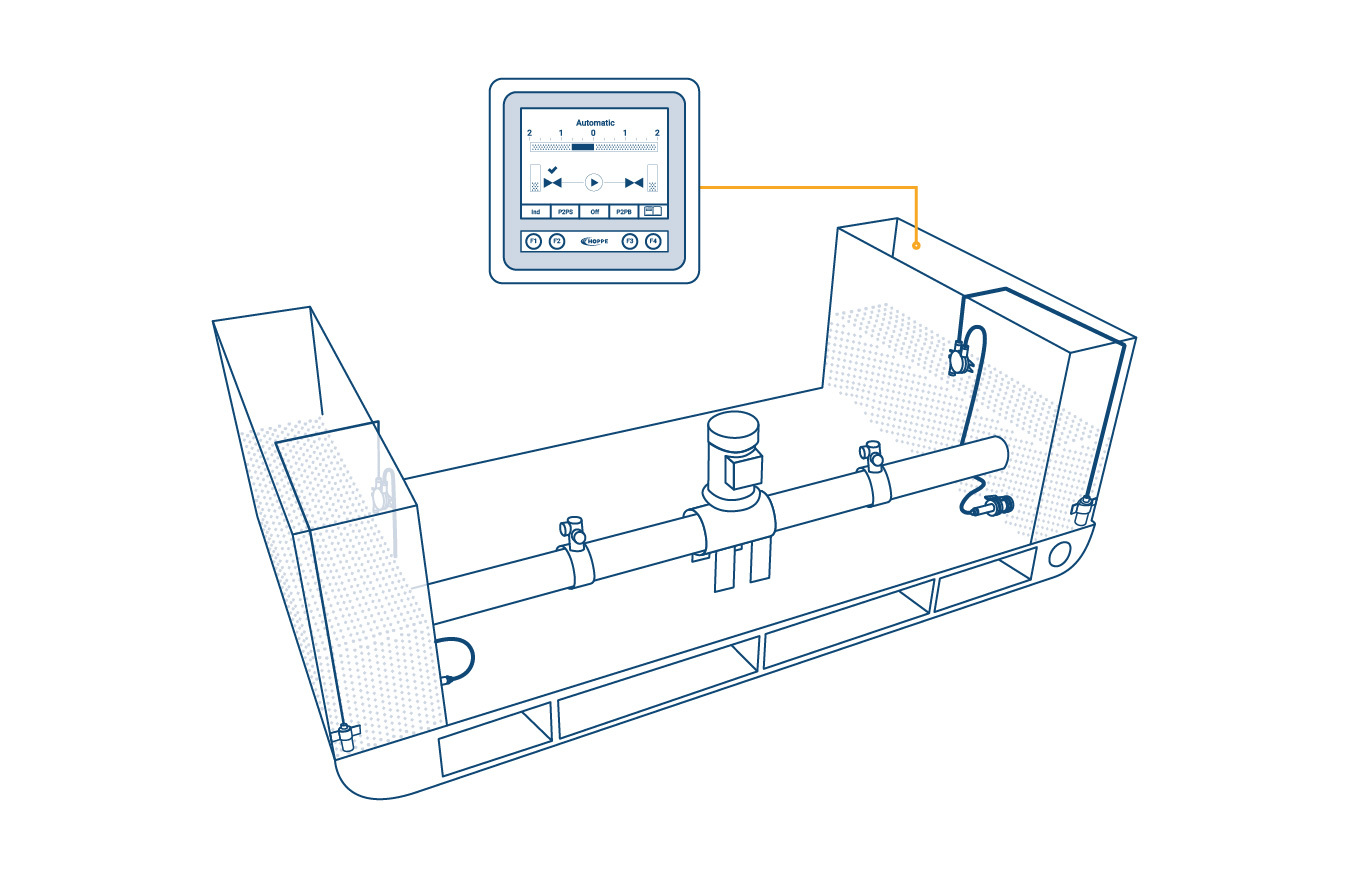

The standard control system offers MANUAL, AUTOMATIC or BALLAST mode operation via HMI – touch screen of PLC unit HOMIP or central PC-Station as well as connections to the alarm and monitoring system (IAS/AMS). In AUTOMATIC mode the system starts to compensate the heel angle when the threshold value exceeds ±0.5 degrees heel. Sophisticated systems, required for loading operations at sea or offshore lifts, are controlled by measuring the actual heel moment generated and adjusting the individual flow rates. Then the control software offers additional operational modes such as ZERO FLOW, FLOW CONTROL and LOAD MOMENT CONTROL. Unique in the market is Hoppe’s ability to combine heel compensation with roll damping functionalities in the same ballast water tank.

- Allocated knowledge of Hoppe, Intering and FLUME® in the design of Heel Control systems

- Experienced Naval Architects design the optimized and cost effective solution for standard and highly specialized applications

- Well proven and reliable key components

- Long reference list in large scale systems with a compensation rate of 10,000 tm/min are supplied and operate at the highest degree of reliability (up to 15 pumps sets or 4 blower units)

- Ice-heeling functionality for ice-breaking and ice-going vessels

- Reversible propeller, centrifugal, screw pumps or air-blower

- Direct start, soft start or frequency controlled electric motors

- Electric pressure sensors for remote sounding of tank content or level switches

- Inertial Measurement System or inclinometer for determination of ship’s heel angle

- Valve Remote Control System to control fluid flow with pneumatic, hydraulic or electro-hydraulic actuators

- Valve group for air flow control between 12” to 23”.

Anti-Heeling

- Description

The heel compensation moment is achieved by transferring ballast water or other fluids between the heeling tank pairs using reversible propeller, centrifugal or screw pumps. Hoppe’s reversible axial propeller pumps are an in-house design especially suitable for bidirectional water shift as required for Heel Control systems. Three different pump sizes are available for vertical and horizontal installation as well as exproof solution. The pump performance is selected for each individual application by varying the gear set and motor type. Flow rates of up to 2,500 m³/h per unit can be provided.

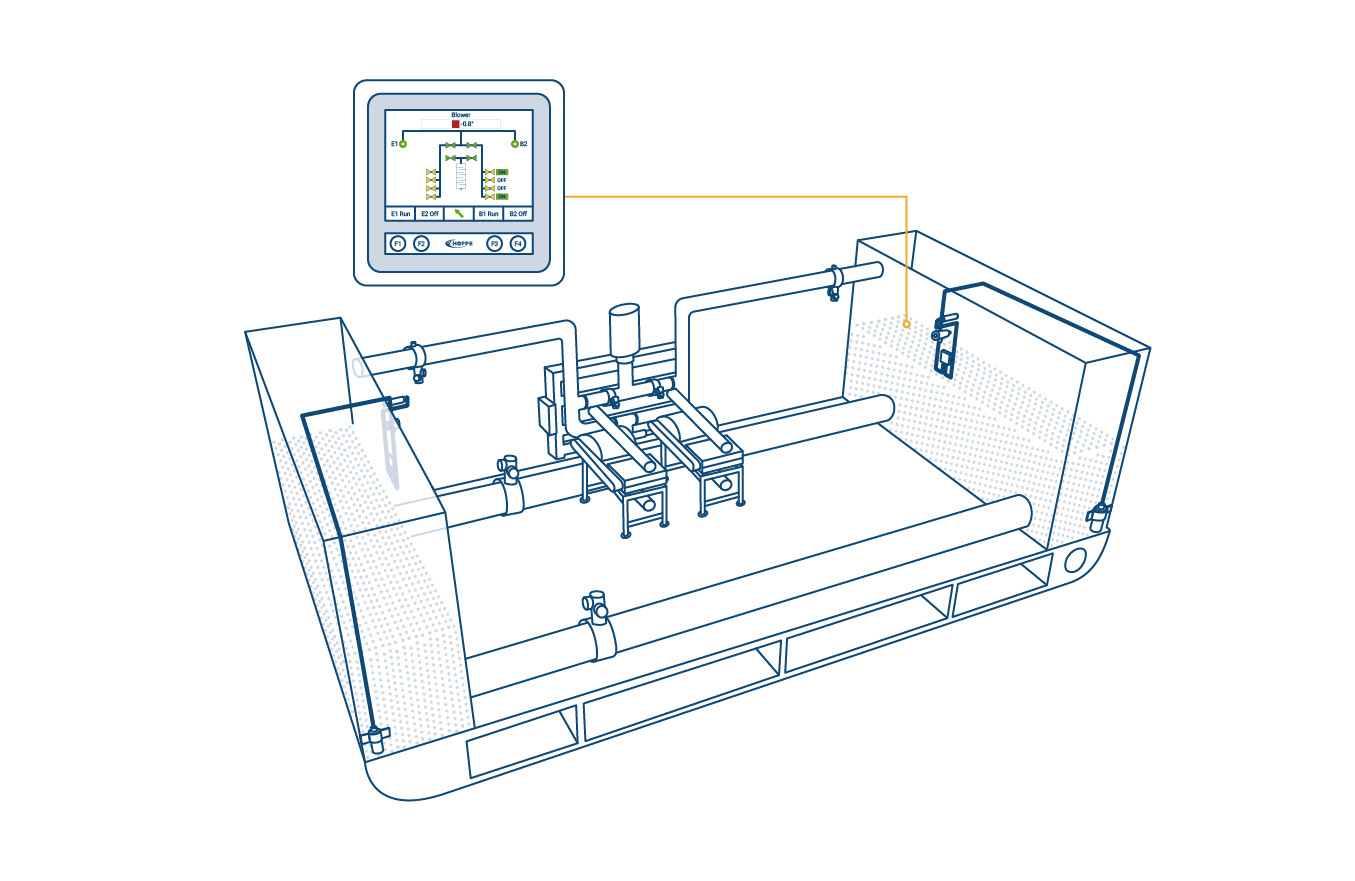

Blower Anti-Heeling

- Description

The closed system consists of one or more ballast water tank pairs which are connected with air-pipes on the top and water pipes close to the bottom. The compressed air from the blower unit(s) is used to shift the water between the tank pairs to generate the compensating moment. The direction of the air-flow is controlled by a valve group to the tank and back to the atmosphere via a silencer. The system has extremely short response times in combination with high compensation rates. Blower Heel Control systems can be combined with U-Tank Roll Damping Systems and Ice-Heeling operational modes can be provided as additional option.