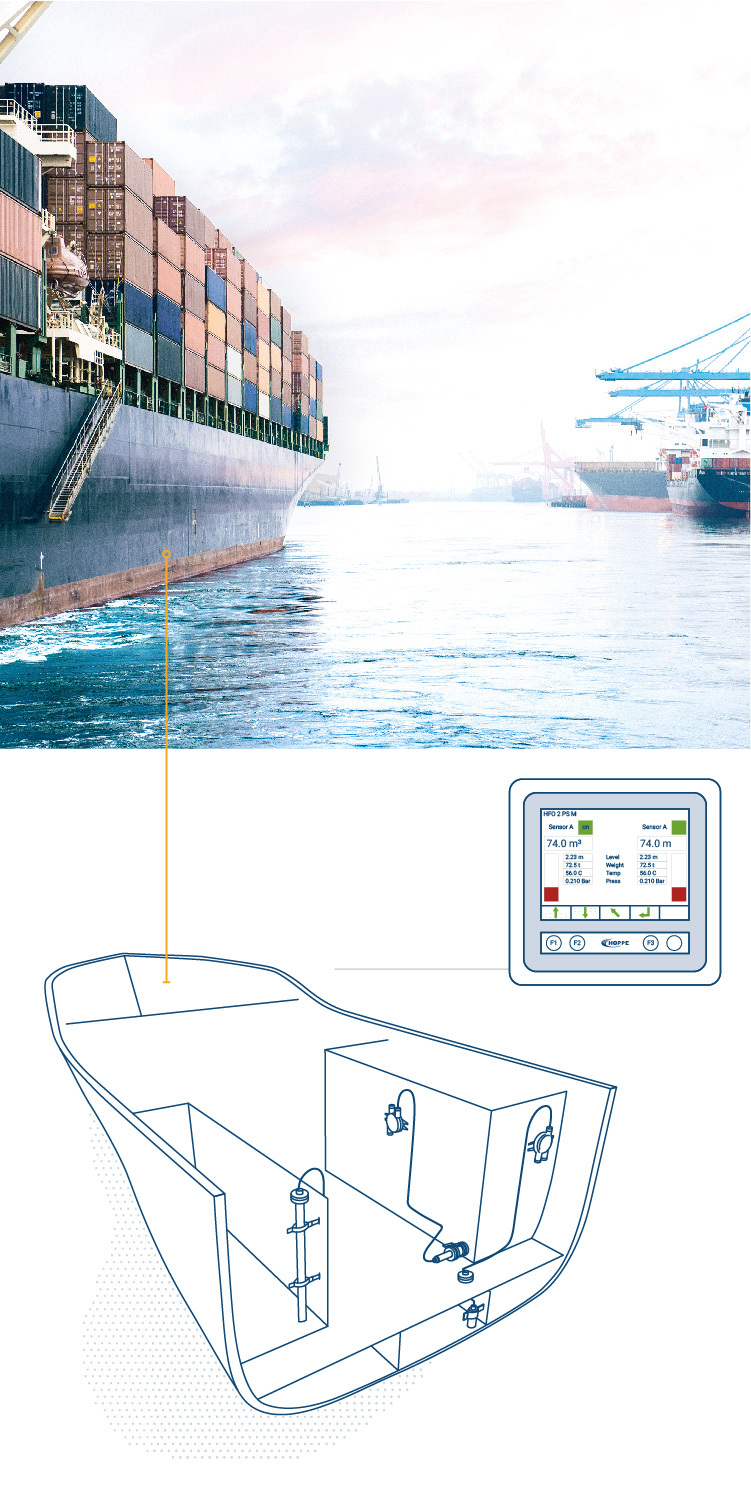

Tank Content Measurement

System Overview

- Description

- Components

Hoppe Marine Tank Content Measurement solutions continuously monitor the contents of ballast, fuel oil and other liquids on board, with various sensor types.

The hydrostatic pressure sensors HCG 2011 and HCG 4011 have been specially developed to detect the levels of wide range of liquids with different media properties. The pressure sensors of the HCG series can be configured to the required measuring range, housing material and process adaptor. They are based on a piezo resistive measuring cell, which converts the hydrostatic pressure into an electronic signal. Measurement with pressure sensors is independent of foaming (cappuccino effect). The pressure sensor HCG 2011 provides a signal of 4 – 20 mA and allows customised measuring ranges, adjustable via HART protocol. The pressure sensor HCG 4011 is designed with a digital serial BUS interface, which allows cost saving cable loop installations.

The electro pneumatic pressure sensors are installed inside control cabinets and measure the liquid level via a system of continuously bubbling air. The measuring unit is fully equipped with all necessary features of air flow indication, air flow adjustment, purge function as well as stop and safety valves in order to protect the measuring cell against liquid ingress.

- Full responsibility for the tank content data

- Reliable and accurate in house designed sensors

- Experience on more than 2,400 vessels worldwide

- Adjustable measuring range up to 4,000 mbar

- Installation savings by usage of BUS type sensor

- Sensor toolbox HOSET for optimized maintenance and lifetime analysis

- Made in Germany with competitive market price

- Approved by major classification societies

Hydrostatic pressure sensors HCG

- HCG 2011 analogue type, 4 – 20 mA

- HCG 4011 digital BUS type

- Stainless steel powder coated or titanium housing

- PT-100 temperature sensor integrated

- Plugable sensor cables

Electro-pneumatic pressure sensors inside cabinet

- Air flow indication and adjustment

- Stop and safety valves

PLC unit HOMIP for tank content calculation

- 6” touch screen

- Trim, list and density correction

- Interfaces to Hoppe or 3rd party systems