Dynamic Draught Measurement

Dynamic Draught Measurement

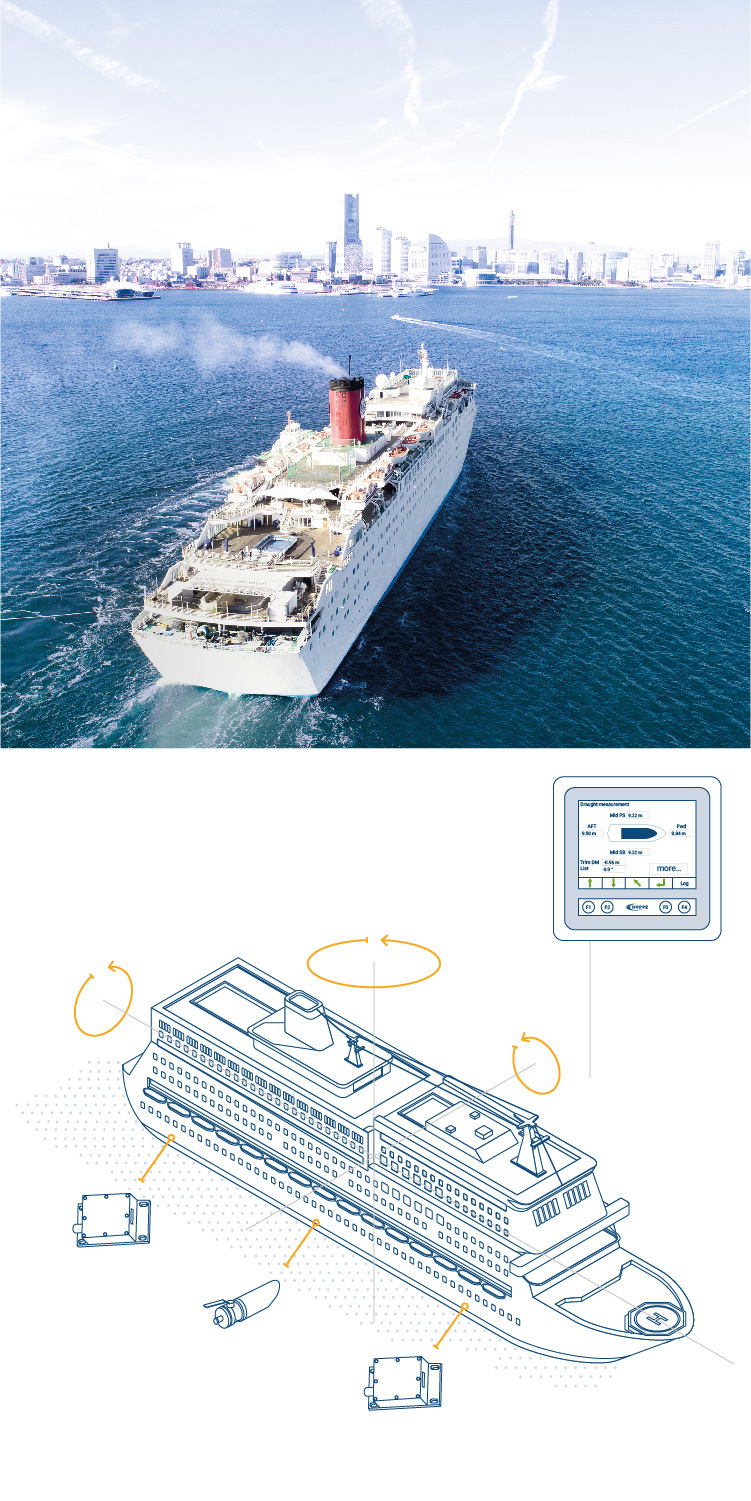

System Overview

- Description

- Key Features

- Components

Hoppe Marine Dynamic Draught Measurement solutions monitor the draught of the vessel and determine the draught values precisely at perpendiculars and draught marks during vessel voyage.

The standard Dynamic Draught Measurement system configuration includes four measuring points with pressure sensors, located at bow, stern, mid ship port and mid ship starboard and two inertial measuring unit HOSIM.

The system delivers precise values unaffected of hydrodynamic effects during vessel voyage.

- Precise draught calculation at perpendicular and draught marks during vessel voyage

- Trim and heel, sagging and hogging information

- Reliable and accurate in house designed sensors

- Made in Germany with competitive market price

- Upgrade possibilities to Dynamic Floating Monitoring

- Valuable data for vessel performance monitoring systems

Hydrostatic pressure sensors HCG

- HCG 2011 analogue type, 4 – 20 mA

- HCG 4011 digital BUS type

- Stainless steel powder coated or titanium housing

- Titanium membrane

Solid class approved welding block unit including sensors

Precise inertial measuring unit HOSIM for vessels movement

and floating condition PLC unit HOMIP for draught calculation

- 6” touch screen

- Including trim, list and density correction

- Interfaces to Hoppe or 3rd party systems