Predictive Maintenance and Self-Validation

System Overview

- Why Predictive Maintenance?

- What Do We Do?

Especially in the maritime environment, predictive maintenance is becoming increasingly important. To reduce costly repair work, predictive maintenance has become a competitive advantage.

The development of algorithms is still in its beginning as part of the Service 4.0 movement but already provides an immense value added to the core components of Hoppe Marine – Ship Performance.

Validated systems with no downtime also represent the basis for further optimization possibilities beyond the actual operational requirements.

For trouble-free operation, the primary parameters of performance measurement, fuel consumption and ship speed are increasingly coming into focus.

The validation of these measured values with early detection of drift rates, offsets or speed-related distortions has an influence on on-board fuel calculation, reporting and further efficiency models.

Hoppe Marine’s increasing focus lies on recognizing and reporting these abnormalities. Data validation thus forms the basis for the information gained from ship operation.

Validation of MAIHAK Torque Power Meter

- Description

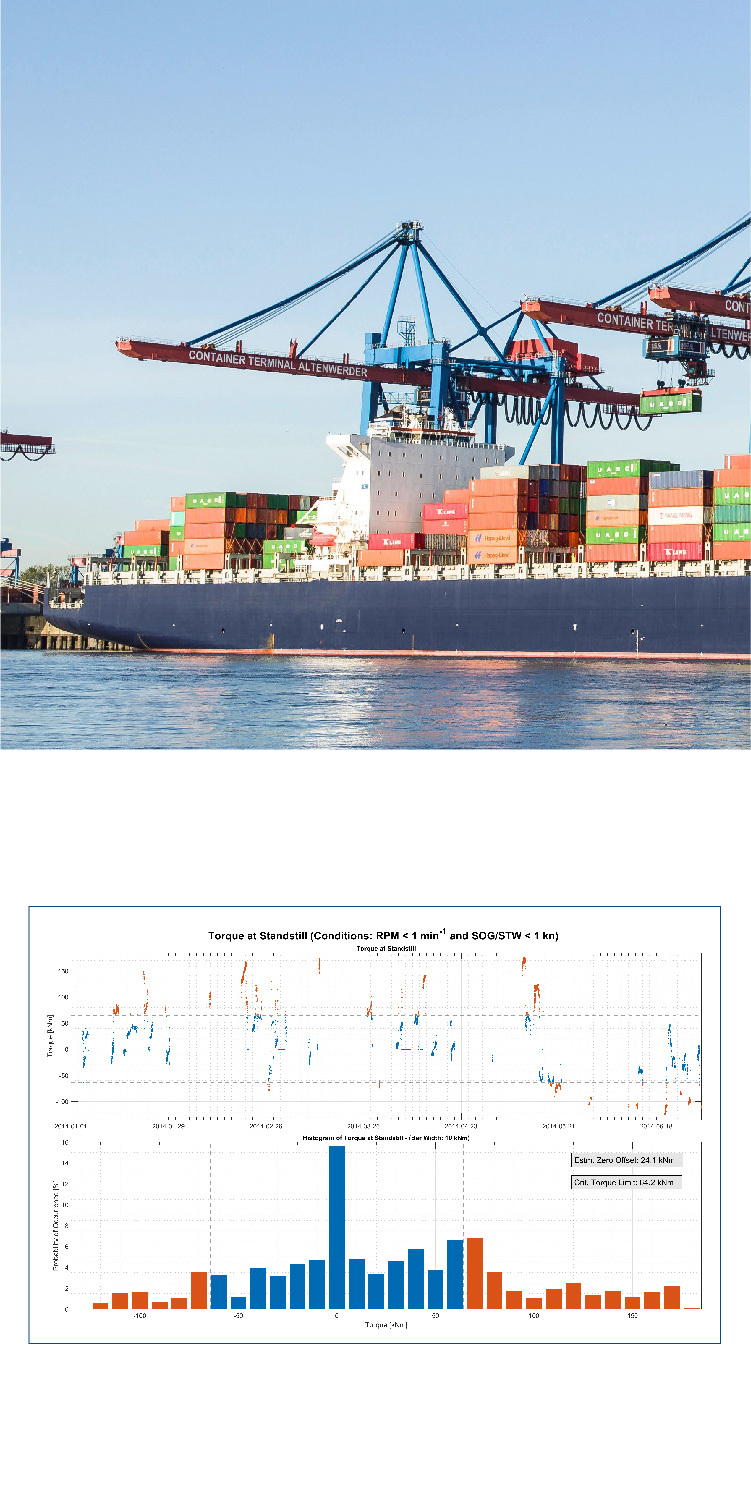

The following methods for the main engine power determination with Maihak Torque Validation show the possibilities of self-validation.

- An offset algorithm informs the user if the engine-specific limit for the torque offset is exceeded during standstill. In this case, a calibration of the system is essential.

- The dashed line shown in the figure indicates this limit for a short-term permitted offset at standstill. If this behavior remains undetected, it can lead to a mismatch of several percent.

- In the dynamic case, the frequencies of the negative-correlating vibrating sides are monitored. If this behavior changes, the user receives a message for implausible operation.